Technical Support

Brake Pads

Yaolun brake pads supply a variety of high performance formulas brake pads for your choose

Features and Benefits:

All brake pad components are tested to meet top quality standards

Superior stopping and Long Life

Excellent brake pedal feel

Ultra-precise backing plate molds for perfect fitment

Steady friction coefficient under elevated temperatures

Exclusive rust prevention treatment on all hardware

Individual 100% slotted and chamfered for NVH control

Maximum safety, comfort and service life

Comprehensive range of application

Ultra low noise emissions

Low rotor surface abrasion

Low dust in the wheels

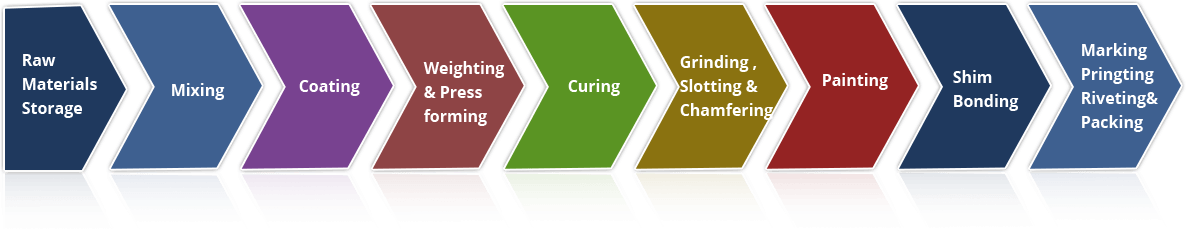

Brake Pad Production Process:

Navigation

Subscribe To Our Newsletter

Stay in touch with us to get latest news and discount coupons