Jul. 15, 2022

Your brakes are critical when it comes to driving safety. We've compiled a guide to help you understand your brakes. This includes disc and drum brakes, how they work, how they are different and similar, why you might use both types on the same vehicle, what kind of wear to expect, and which parts need maintenance.

● What is a simple braking system

● Brake system basics

● The basics of disc brakes

● The two types of disc brakes: floating and fixed

● Basics of Drum Brakes

● Drum vs. Disc Brakes

● Brake Maintenance

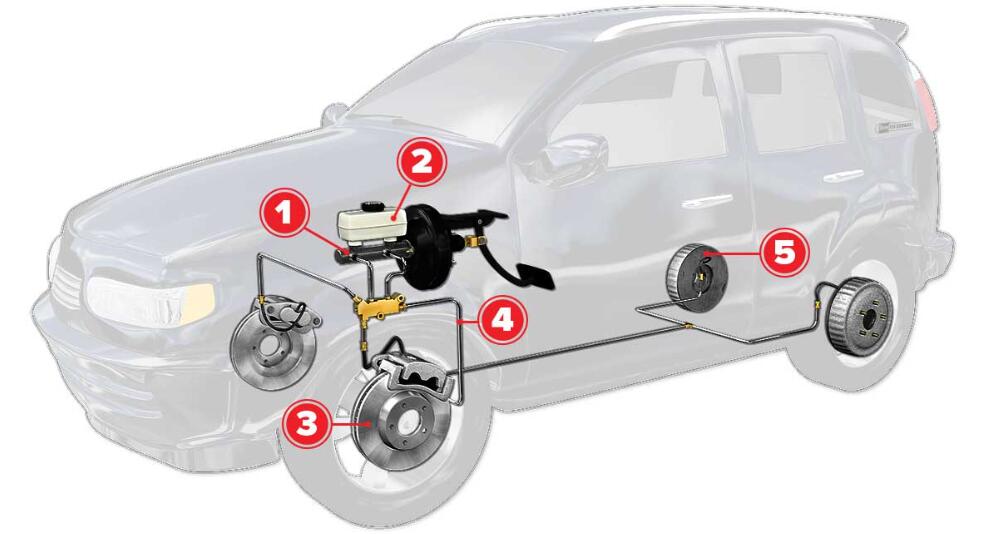

1. Master cylinder: Contains the piston assembly and brake fluid.

2. Brake fluid: transmits hydraulic pressure.

3. Disc brake assembly: includes calipers, pads and rotors.

4. Brake lines and hoses: transfer brake fluid to the brake assembly.

5. Drum brake assembly: includes brake shoes, wheel cylinders and drums.

Disc and drum brakes are based on hydraulic systems. Braking starts with mechanical force - your foot pressing the brake pedal. The end result is that your vehicle stops safely. Here is a brief description of the five points of the system:

1. The piston compresses the brake fluid in the master cylinder located under the hood of the vehicle near the engine. This creates hydraulic pressure, creating a force greater than the small force of depressing the pedal.

2. The pressure is transmitted through the brake fluid through the brake lines and/or the brake hoses (hoses) that connect the lines to the brake components on each wheel.

3. There, the wheel cylinders convert the hydraulic pressure back to mechanical force. The brake friction material is pushed against the brake discs or drums, slowing or stopping your vehicle.

4. The disc brake assembly is designed to safely stop your vehicle when activated. For more detailed information on how they work, see below.

5. Drum brake assemblies equipped on some vehicles are also designed to stop your vehicle when activated at other points on the system. More details are provided below.

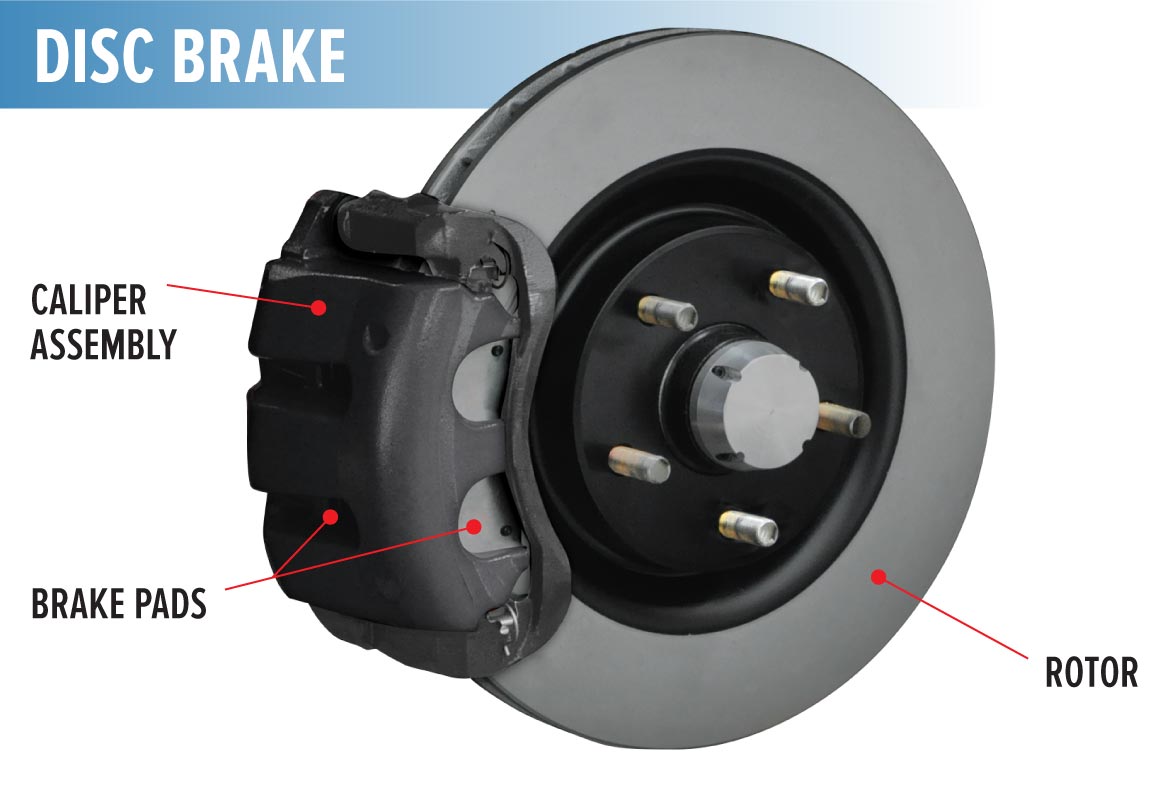

Today, most vehicles are equipped with disc brakes. They are mounted on the front and/or rear axle. To stop the wheels (and your car), disc brakes use calipers with brake pads to grip the spinning disc or rotor.

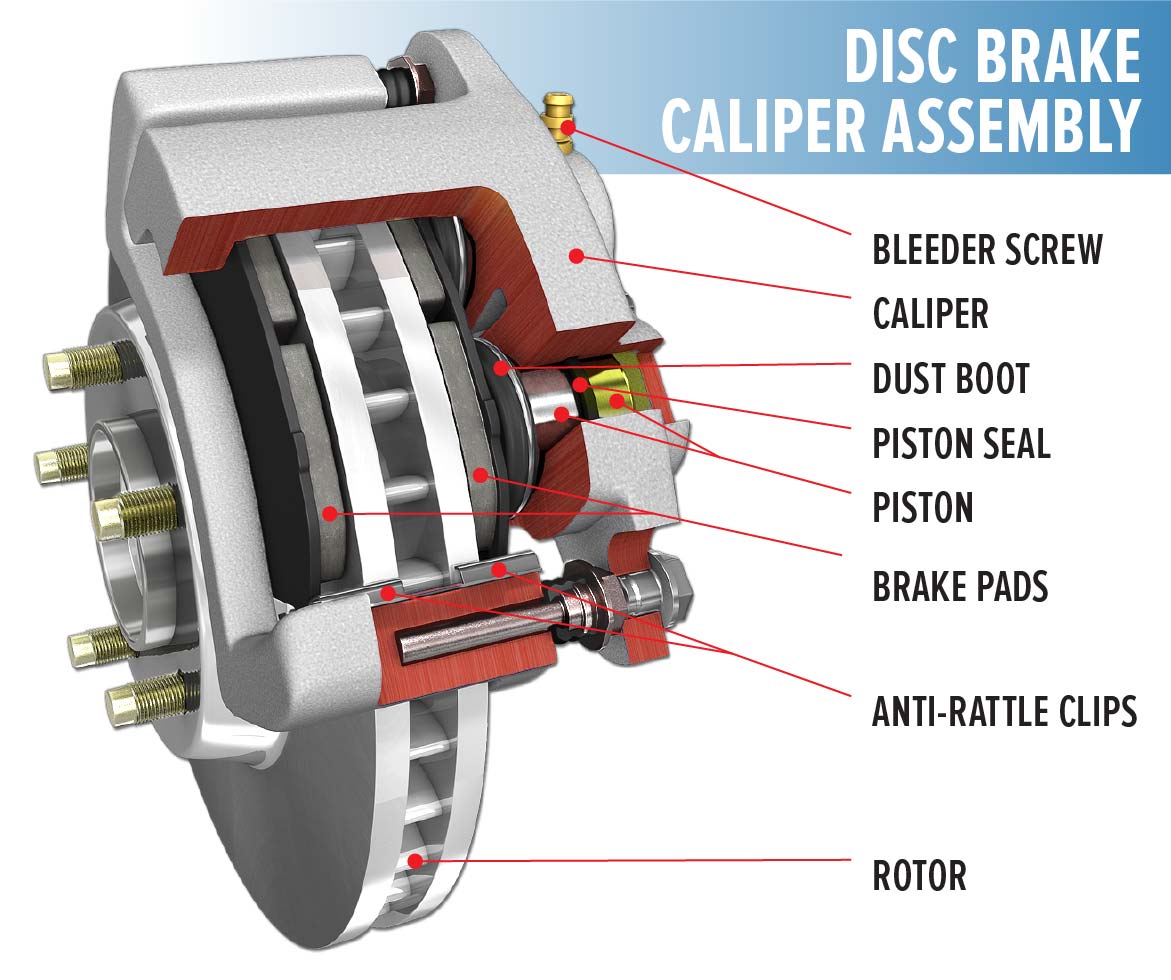

A caliper is a component that is mounted to the vehicle via a bracket. It forms the frame of the rotor and is similar in appearance and function to a c-clamp. It contains the following components.

● A brake pad is a friction material bonded to a metal plate that helps you stop your vehicle.

● One or more pistons that push the brake pads against the rotor when the brakes are applied.

● A bleed screw for brake service and fluid changes.

● A rubber piston seal that prevents brake fluid from leaking and retracts the piston when the brake is released.

● A dust sleeve to prevent contaminants from entering the cylinder.

● Anti-vibration clips for added stability.

The rotor is made of cast iron or a steel/cast iron composite. It is attached to the wheel hub and rotates with the wheel. It is the surface that the brake pads touch to slow down the vehicle. Here's how it works: When you apply the brakes, pressurized brake fluid pushes a piston inside the caliper, forcing the brake pads against the rotor. As the pads press against the sides of the disc, friction stops the wheels from spinning.

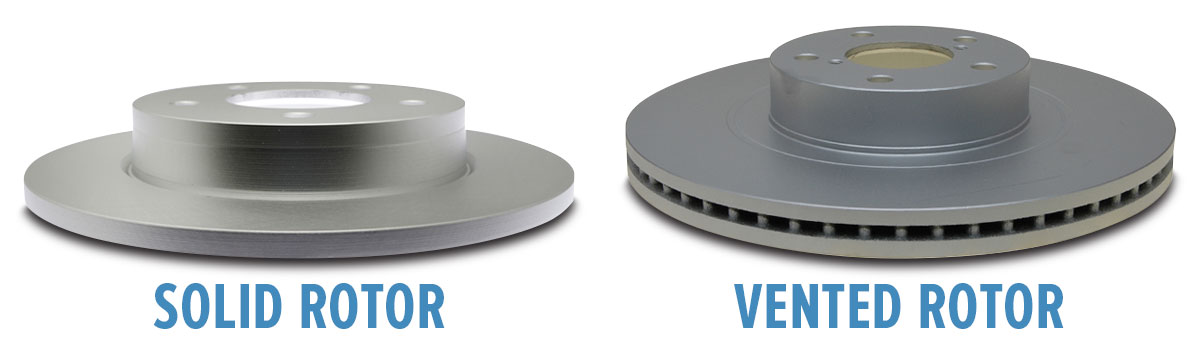

Rotors can be solid or vented. Vented rotors have a larger surface area and dissipate heat more easily.

There are two types of disc brakes. They are floating and fixed and are named after the type of caliper used.

The floating caliper (also called a sliding caliper) is the most common type. It has one or two pistons. When the brakes are applied, the inner brake pads are pressed against the brake disc while the caliper body leans toward the rotor. This action forces the outer brake pads against the rotor.

The fixed caliper design has one or more pistons mounted on each side of the rotor. The caliper itself does not move or shift. It is securely fastened to the caliper bracket or spindle. When the brakes are applied, only the caliper pistons move, pressing the brake pads against the brake disc.

Drum brakes are most commonly used on the rear axle of today's vehicles. They are also common on trailers. Manufacturers do not use brake pads as the friction material for drum brakes. Instead, drum brakes have a wheel cylinder with pistons that push the brake shoes out to the inside of the rotating drum. This contact slows and stops the rotation of the drum and the wheel, which stops your vehicle.

Many of today's vehicles are equipped with disc brakes on all four wheels. However, some models still have disc brakes on the front axle and drum brakes on the rear axle.

Why are discs on the front? This is due to the weight factor. Because of the engine, the front of a typical unladen vehicle weighs about 10%. When you apply the brakes, the weight of the car shifts to the front. As a result, the front wheels need more braking power, making disc brakes perfect for this job.

Servicing disc and drum brakes is important. In terms of maintenance, drum brakes have more hardware and can be more complicated to repair. However, the cost of these materials is usually lower than disc brake pads, calipers and rotors. Disc brakes typically contain fewer components and are easier to service.

A lot of heat is generated when you apply the brakes. When you press the brake pedal, you convert the kinetic energy (motion) of your vehicle into heat (heat), exposing many components to extremely high temperatures. This means a lot of wear and tear, even under normal conditions. Some brake parts need to be replaced throughout the life of the vehicle, including.

● Brake pad or brake shoe friction material: Disc brake pads slow down the rotor through friction and wear during normal use. Eventually, they become too thin to work properly. This also applies to drum brakes. The friction material will wear and braking may be compromised. These parts should be checked periodically to prevent wear to the point of causing damage to other parts of the vehicle (rotors or drums).

● Brake Fluid: The brake system should be checked periodically for leaks and the brake fluid should be changed every few years (usually when the brakes are serviced). Any leaks in the master cylinder, brake fluid reservoir, wheel cylinders, lines or hoses will reduce the hydraulic pressure generated when the brakes are applied. If the system does not produce enough force to generate braking power, you will notice that you need to depress the brake pedal further to slow or stop.

● How often should I change my brake fluid? : Brake fluid should be changed every few years. This is usually done when the brakes are serviced. Although brake fluid is specially formulated to prevent corrosion of the brake hydraulic components, time, heat and moisture will lower the fluid's boiling point. This can reduce the pressure in the hydraulic system, forcing you to depress the brake pedal further to slow down the vehicle. Other contaminants, such as road grime, brake dust, and rust, can enter the brake fluid, reducing brake efficiency and potentially damaging brake system components.

● Seals: These rubber rings prevent hydraulic fluid from leaking and protect it from moisture and contamination. They also return the piston to its closed position, so the brake pads will disengage properly when you release the brake pedal. If this does not happen, you may experience brake resistance, premature wear, and the vehicle may pull to one side when you brake.

● Brake Lines/Hoses: Brake lines and hoses are an important part of your brake system. Rubber hoses can wear over time, and brake lines can become corroded or otherwise damaged. When this happens, it may affect braking efficiency, loss of hydraulic pressure, pulling to one side, etc. Routine inspections, including hoses and lines, are critical to avoid these problems.

● Rotors: Rotors should be checked periodically for uniform wear, physical damage, or cracking due to overheating. These conditions can affect braking power and efficiency. When servicing brakes (replacing brakes or pads), the discs should be reground or replaced. If you experience any of the previously mentioned problems, your rotors may need to be repaired or replaced as soon as possible.

● Dust shields: Brake components are often exposed to road debris and brake dust. The dust shield prevents dirt from entering the caliper piston. If it fails and does not do its job, piston damage can occur, resulting in brake drag, pull and premature wear.

● Master cylinder: Regular fluid maintenance is important to extend cylinder life. A faulty master cylinder may be leaking internally. In this case, you may feel a low or soft pedal. You may not notice any significant loss of body fluid.

Disc brakes and drum brakes are constructed differently and offer different benefits. Both work as part of a hydraulic brake system. The system is always under high pressure, subject to heat, and can be affected by road grime, air, brake dust, and moisture. It is important to check the brakes regularly to keep everything working properly.

Related News

Function and Characteristics of Automotive Clutch

Jun. 28, 2023

Brake Shoe vs. Brake Pad: What's the Difference?

Jun. 16, 2023

Common Signs of Worn-out Brake Shoe

May. 26, 2023

Product Categories

Brake Pads MKD2173 LEXUS,TOYOTA GS,IS,SC,Crown,Majesta, Royal 1jz ,2jz,1G 1997-2011 REAR

Brake pads MKD2082 TOYOTA L/C 1990-1998 Lexus LX450 1996-1997 FRONT

Brake pads MKD2023 Toyota AE90/100/110 Caldina,Carina,Corolla,corona front 1998-2002

Brake pads MKD1233 NISSAN Almera II CC 1.5,1.8,2.2 2002 Front

Brake Pads MKD-11201 HYUNDAI SANTA FE CC 2.2,2.7(HUATAI)front

Brake pads MKD-0038 DAIHTSU Cuore VI(L7),Hijet, PERODUA,1998-2003

Navigation

Subscribe To Our Newsletter

Stay in touch with us to get latest news and discount coupons